IEEE Visualization Contest 2011

Official event of the VisWeek 2011

Data

The data description is also available as

pdf

(last update 15.06.2011). The donwload links can be found at the

bottom of this page.

We require that any publications (not the contest entries) using any

of these datasets include the following acknowledgment:

The data is courtesy of the Institute of Applied Mechanics,

Clausthal University, Germany (Dipl. Wirtsch.-Ing. Andreas Lucius).

We provide 3 data sets of the same centrifugal pump, each obtained with a

different turbulence model.

In principle, there are three general approaches: LES, RANS, and the

hybrid LES/RANS. Each approach represents a class of models; so for

each approach, there are many more or less different models.

The centrifugal pump uses a spinning "impeller"

which has backward-swept blades.

The RANS model

The state of the art turbulence

modelling is derived from averaging the Navier Stokes equation in

time (Reynolds Averaged Navier Stokes, or RANS). During this

averaging process the Reynolds stresses appear as additional unknown

variables. Most models are based on the eddy viscosity concept,

where the influence of turbulence fluctuations is modelled by the

introduction of an additional eddy viscosity. These models are based

on some crude assumptions and especially fail in strongly separated

flows.

The LES model

Another approach for the computation of turbulent flow is the direct

simulation of turbulence down to the grid size and modelling only

turbulence at smaller scales. The LES (Large Eddy Simulation)

approach requires very fine grids and time steps to resolve the

important turbulent structures, which makes it unfeasible for high

Reynolds number flows in complex industrial geometries.

The hybrid LES / RANS model

A mixed approach is hybrid LES / RANS modelling: a standard

turbulence model is used for attached regions and switches to LES in

strongly separated regions. This reduces the computational effort in

comparison to pure LES and improves accuracy in comparison to pure

RANS simulations.

Nevertheless, massive parallelization is required to solve the 3D

transient simulation modell.

Data description

Each data set comprises one full rotation of the centrifugal pump

consisting of 80 time steps.

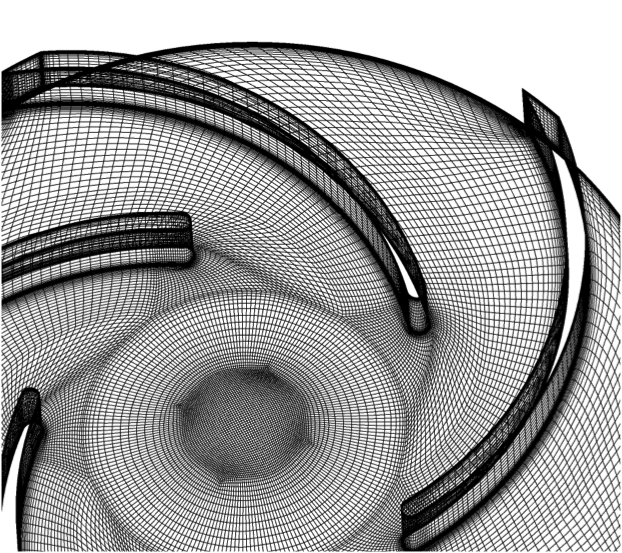

The numerical setup comprises 6.7 mio nodes and 6.4 mio

cells,

respectively. The setup contains 2 stationary domains (inlet and diffuser)

and the moving rotor domain.

Because the hybrid models are the state-of-the-art today, two of the

models we have chosen are from this class, namely DES

and SAS.

DES was derived from the LES approach, while SAS is based on the

URANS (= Unsteady RANS) approach.

The third model we have chosen, SST, is a model of

the RANS class, which are the classical turbulence models, some of

which exist for tens of years. We have chosen SST because it is one

of the best in its class.

LES is (at least, currently) not feasible for complex geometries and

high Reynolds numbers, because of the sheer amount of nodes

necessary.

See our

reference section for

further information.

The visualization should look quite different when

applied to the SST data set versus the other two hybrid models (DES

and SAS): in the DES/SAS data sets, turbulent structures are

resolved in massively separated regions. For this reason one should

see much more detailed structures in comparison to the SST data set.

SST does not resolve turbulent fluctuations; only time-dependent

average values can be computed. For the other two models turbulences

can be directly resolved using a sufficiently dense grid.

Explaining the variables:

For each node, a

couple of variables are available:

- total pressure

- total pressure in stn frame

- turbulence kinetic energy

- velocity

- velocity in stn frame

Pressure:

static pressure

Total pressure:

static pressure plus kinetic energy of the relative velocity in

pressure units

Total pressure in stn frame (=Total pressure in 4):

static pressure plus kinetic energy of the absolute velocity

Turbulence kinetic energy (=Turbulence kinetic 5):

kinetic energy of the turbulent fluctuations of the velocity. Using

SST, the whole turbulence is modeled (k-Omega model, k is the

turbulent kinetic energy). With SAS or DES the modeled kinetic

energy is clearly smaller as the turbulent fluctuations in the flow

field are resolved.

Velocity:

velocity in the relative system (rotating with the impeller)

Velocity in stn frame (=Velocity in Stn Fr 7):

velocity in absolute system (observed from fixed generator casing).

As there are two different velocities, there are also two different

formulations of the total pressure.

A word about the terms "absolute

velocity" (= "velocity in stn frame") and "relative velocity" (new

15.06.2011)

First of all, all vectors and points are defined in a global

Cartesian coordinate system, which is the same for all different

kinds of velocity.

The fluid at a point p in space has some absolute velocity

c.

If this point p is a point on the surface of the rotor, it

moves on a circle around the axis of the rotor; this point p,

then, has some other velocity u (which is exactly

tangential to the circle). Thus, we can define the 'relative

velocity' w of the fluid at p, which is w

= c - u.

In other words, an observer sitting at p and moving along

with p (but always looking in the same direction in the

global coordinate system!) would observe the fluid in point p

moving with a velocity w, while an observer sitting still

relative to the global coordinate system would observe that same

fluid in point p having velocity c.

The velocity of point p can be derived from the rotational

velocity omega of the rotor by u = omega x r,

where r is the vector from the rotor's axis to p

(and perpendicular to the axis).

These notions can, of course, be extended to any point in the domain

of the rotor. In addition, it is understood that all vectors and

positions are functions of time.

PS: why would one want to express the same velocity in two

different ways?

Because some differential equations are easier when expressed

over the relative velocity, while others are easier when expressed

over absolute velocity.

A word about the grids:

Even though the rotor physically moves in time with

constant rotational speed, the flow inside the rotor is calculated

with a stationary grid. The relative movement of rotor and stator

domains is captured with the usage of transient rotor stator

interfaces. The interface properly connects the nodes on both sides

at rotated position.

For that reason the geometry is static for all files. (If the

original data is post processed with CFX, the rotation of the grid

is automatically done.) For any other tool the rotation needs to be

done by the user. Despite the fact that rotation of the impeller is

physical, analysis may be more appropriate for a stationary rotor

depending on the task. Tracking the movement of vortical structures

is easier without superposition of the rotation of the rotor.

For your information: the rotor domain contains all volume elements

named with "ROTOR_VOL". It rotates with a velocity of -600

revolutions per minute around the Z axis (using the right-hand

rule). The time step between two transient files is 1.25E-3 seconds,

which corresponds to 4.5 degrees.

A bit more about the names of the elements:

The following surface elements are also part of the rotor volume:

-

"Bodenscheibe",

- "Deckscheibe",

- "Deckscheibe Spalt",

- "LR Diffusor",

- "Schaufel",

- "Spalt Gehaeuse"

The following surface elements are the interfaces:

-

"Eintritt Rotor 1 Side 2"

- "Eintritt Rotor 2 Side 2"

- "Rotor

Diffusor Side 1"

- "Spalt SS Side 1"

File Formats

The data can be downloaded in two different formats,

Ansys 12.0 CFX and EnSight.

The Ansys CFX files might be useful for people already

having an Ansys license.

The EnSight files can be imported by many applications and libraries

(e.g., VTK,

ParaView,

VisIt) and might

also be useful for people who have already a

EnSight license, or participants can use EnSight CFD Free edition,

www.ensightcfd.com. EnSight

standard trial licenses will be provided upon request (write an

email to Eric O'Connell). EnSight CFD

Free version does not require a license and can be simply downloaded

and used without a license key.

The EnSight files are ASCII files, so they can be loaded

by home-grown visualization software. The files are in the EnSight

Case Gold format, which is described in Chapter 12 of the EnSight

User Manual, which can be downloaded here:

http://www.ensight.com/Download-document/180-User-Manual.html

If you would like to get a copy of the data in another format,

please contact us, and we will see whether we can do something for

you.

Test data

If you would like to develop your own loader for the

EnSight files, you might want to test your loader with

the following toy example.

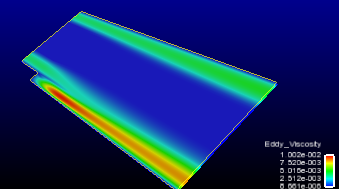

EnSight Gold file format:

download

Visualization of the test data. In this case,

the scalar "Eddy_Viscosity" is used.

Contest data

All 3 data sets in both formats (CFX / EnSight) can be downloaded from following two locations

Note the LARGE file size and ensure sufficient disk space

when extracting. The extracted files will need about 500GB.

Acknowledgements

The data is courtesy of the

Institute of Applied Mechanics, Clausthal University, Germany (Dipl.

Wirtsch.-Ing. Andreas Lucius).

Web and data hosting

for VisContest is provided by courtesy of SDSC, TeraGrid and

Clausthal University.

Early Registration

Notification

September, 9th, 2011

Deadline

July, 31st, 2011,

23:59 PST